Multi-Purpose Grease

Automotive multi-purpose grease is a versatile type of grease designed to provide lubrication and protection to various parts. As the name suggests, it can be used for many purposes, making it a convenient and cost-effective solution for vehicle maintenance.

It is typically made from a combination of base oils, thickeners, and additives. The base oils provide lubrication, thickeners help to hold the grease in place and prevent it from leaking or dripping and the additives can improve corrosion resistance, high-temperature performance, and water resistance.

Copper Grease

Copper grease or CopperEase is a grease made with a high concentration of copper particles, designed to prevent metal-to-metal contact, corrosion, and seizing of threaded fasteners and fittings.

It is typically used in high-temperature and high-pressure applications and commonly applied to spark plug threads, exhaust system bolts, brake caliper bolts, and other threaded fasteners that are subject to high temperatures and corrosive environments.

It is not a lubricant, but rather an effective and reliable anti-seize compound.

CV Grease

Also known as Constant Velocity joint grease is a type of high-performance grease that is specifically designed for use in CV joints. These joints are used in vehicles with front-wheel drive and all-wheel drive systems, and they allow the drive shaft to transmit power to the wheels while allowing for the up-and-down motion of the suspension.

In addition to its use in CV joints, CV grease can also be used in ball joints, tie rod ends, and other suspension components due to it being highly resistant to water, chemicals, and other harsh substances.

When applying CV grease, it is important to ensure that the joints are clean and free of any old grease or debris. The grease should be applied evenly to the joint, making sure that all surfaces are covered. Over greasing should be avoided as it can lead to excess heat and pressure buildup, which can damage the joint.

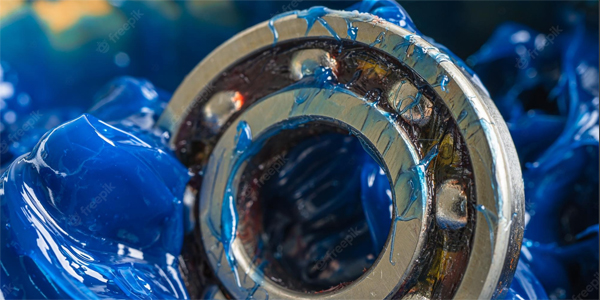

High-Performance Bearing Grease

High-performance bearing grease is a type of lubricant that is specifically designed to provide superior lubrication and protection to bearings in high-performance applications. These applications typically involve high speeds, high temperatures, and high loads, which can cause significant wear and tear over time.

It is essential for the proper maintenance of bearings in high-performance applications. Its improved lubrication and protection properties help to extend the life of bearings, reducing maintenance costs and downtime, and improving overall performance and reliability.

Marine White Grease

Marine white grease is specifically designed for use in marine applications, such as boats, yachts, and other watercraft. It is typically made from a combination of mineral oil, calcium sultanate complex thickener, and other additives such as corrosion inhibitors and water-resistant agents, allowing it to be high resistant to salt water.

It is white in colour to prevent staining and discolouration of the surfaces it is applied to.

Ceramic Brake Grease

Ceramic brake grease is typically made from a silicone-based formula, which is designed to be resistant to water and high temperatures and provides excellent lubrication and protection to the braking system.

The grease is also formulated with ceramic particles, which help prevent noise and vibration by filling in gaps between the brake pad and calliper.

Ceramic brake grease is an essential lubricant for modern automotive braking systems equipped with ceramic pads. Its superior lubrication and protection properties help with proper operation and prevent noise and vibration, improving the overall performance and reliability of the brakes.